CNC Machines

Over 70% of modern manufacturers in USA and UK depend on the use of CNC machines, and skilled machinist jobs are well-paying and abundant in number. Laboratory education in CAD/CAM software and CNC machine programming and operation is central to the teaching of mechanical, manufacturing, and production engineering students at the undergraduate level. However, in many Indian engineering educational institutions, the CAD/CAM and Manufacturing Technology Laboratories are equipped mainly with large commercial CNC machines which are prohibitively expensive and moreover are overdesigned considering the pedagogical needs of undergraduate students. They come with costly annual maintenance contracts and are time-consuming and expensive to repair in the case of breakdowns.

Many academic institutions seem to have (if at all) one each of the CNC mill and CNC lathe, and mainly because of accreditation requirements. As these are expensive commercial grade equipment,

Many of these arguments hold good in the case of polytechnic colleges in India, which are very hands-on and are in need of affordable laboratory CNC machines. The situation is similar for specialized equipment like PCB prototyping machines. So, it is desirable to come up with in-house, build-your-own (BYO), or do-it-yourself (DIY) design, development, and testing of laboratory equipment and systems. Low-cost, desktop and small-to-medium-sized CNC machines such as mills, lathes, routers, and laser and plasma cutters can be built with an open structure so that the construction of the machine is clear and understandable to the students. The cost of the machines may be minimized by using inexpensive yet sufficiently powerful off-the-shelf stepper motors and servomotors with motor drivers. Legacy controllers can be replaced with PC-based control systems with open-source microcontrollers/microcomputers as low-cost data acquisition (DAQ) cards. Open-source CAD/CAM/CNC machining software can be used for design and machining.

3D Printers

3D printers are the best prototyping equipment widely used in makerspaces across the world. 3D printers take the CAD model as the input and build parts layer by layer. Until 2009, 3D printers have been the most expensive capital intensive equipment. FDM or polymer material extrusion-based 3D printers are popular in the open-source world and are very cheap to build. TLC has built many 3D printers using the RepRap platform and it is one of the very useful tools to build complex 3D dimensional objects. Resin-based printers are also becoming cheaper to build with the commercial off-the-shelf motors and frames and TLC is currently developing liquid resin and powder-based 3D printers. TLC at IIITDM Kancheepuram is also building wire arc-based metal deposition 3D printers for prototyping and learning purposes. Two platforms are utilized for building 3D printers one using an aluminium frame and another one using parts build using 3D printers themselves.

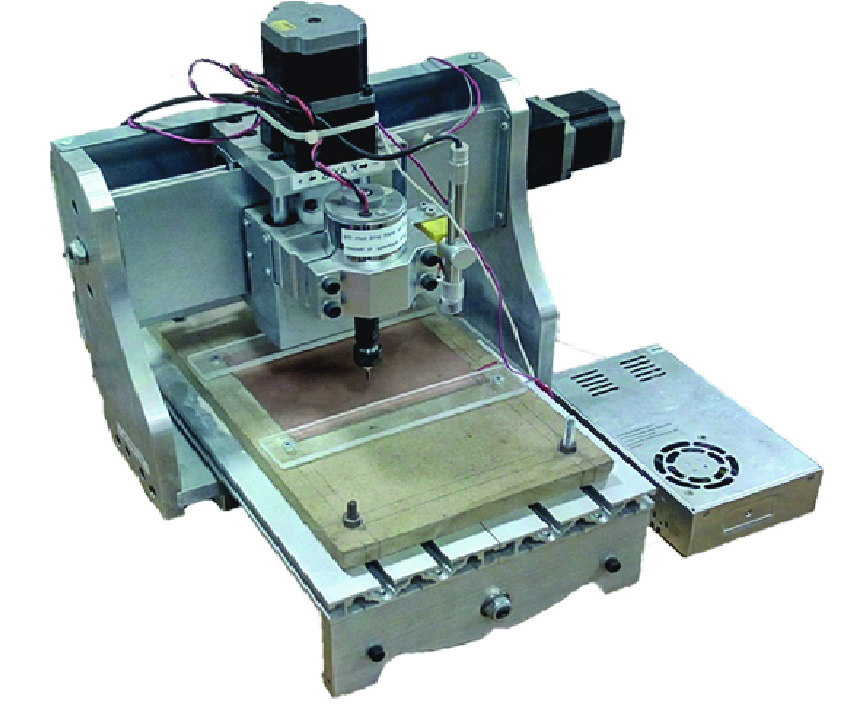

CNC Mill

CNC milling machines and lathes are used for basic subtractive manufacturing in industry, and so engineering students need extensive CNC machining skills. Our DIY/BYO CNC milling machine is a benchtop system assembled from low-cost commercial off-the-shelf (COTS) components like PVC boards, linear screws, guide rods, etc., along with low-cost stepper motors (NEMA17 or 23), motor drivers, Arduino microcontrollers, and sensors like limit switches. The CNC machining is done with free open source CAD/CAM/Simulation/motor control software. Soft materials like (machinable) wax, wood, acrylic and Delrin can be used for practising milling operations. The prototype can readily be scaled up to larger and more powerful milling machines capable of operating on hard materials like non-ferrous metals and MS/SS, and additional subsystems like Automatic Tool Changer (ATC) and pneumatic tool holder can be designed and developed as desired.

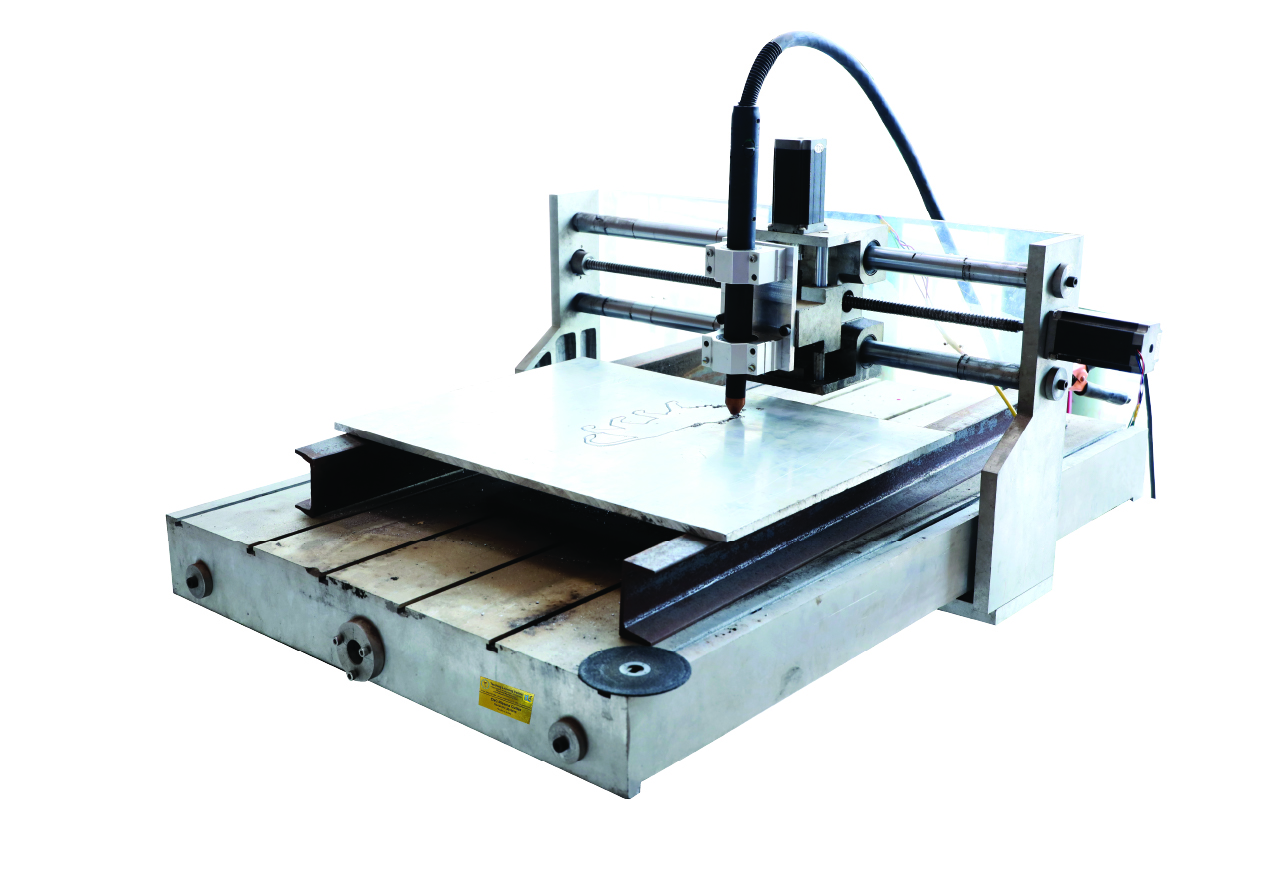

CNC Laser/Plasma Cutters

Presently, the materials used for the mechanical frame of TLC CNC machines is either PVC or plywood. The parts of the frame can be cut manually with power tools like the band saw or table saw, but have limited tolerances and precision of assembly. More accurate parts are also fabricated partly using our own large CNC router (30cm x 60cm).

For sturdier construction and reliable machining of soft metals like mild steel and aluminium, a metallic CNC frame is needed which needs precision metal cutting and/or commercial-grade CNC machines which are beyond our reach. Therefore, larger size CNC frames are currently being procured from commercial vendors.

Currently, the TLC team is planning to design and develop a CNC plasma cutter and later a high-power CNC laser cutter, by retrofitting motor-driver-controller and power transmission assemblies onto the CNC frames. It is hoped that the plasma cutter will enable fabrication of small and medium-sized CNC machines reliably and rapidly. Details on the plasma/laser cutter assembly and performance will be publicized when the work is completed.

PCB Prototyping machine

Design and fabrication of printed circuit boards (PCB) are a basic skill needed in electrical and electronics engineering education. However, many engineering institutions lack access to PCB machines due to high cost and annual maintenance cost, and difficulties in maintenance and repair. A very low-cost DIY PCB prototyping machine constructed with a CNC machine, on-board microscope, and open-source PCB software can be used in electronics laboratory classes and faculty/student projects with significant learning outcomes. The machine is capable of semi-automatic fabrication of double-sided PCBs, with isolation routing/milling, and drilling.

It is planned to pursue future work on the pick-and-place mechanism so that the PCB assembly can be made fully automatic. Surface mount technology (SMT) PCB milling is also currently being studied using our PCB prototyping machine.

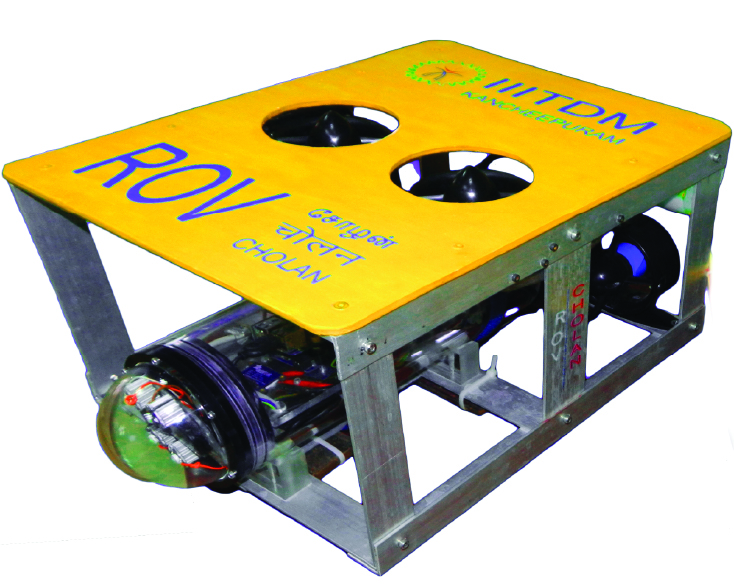

Mobile Robots

Mobile robots come in all sizes and types – ground, underwater, aerial and legged robots – and constitute an active area of research, development and education. Mobile robots are a simple and inexpensive platform for hands-on multidisciplinary engineering education, as they involve design, mechanical fabrication, sensors, motors/actuators, controllers, and software. Nowadays, many mobile robots are controlled over the Internet, or with mobile phone apps (so-called mechatronics). Mobile robots are fun to build and operate, and so are used in schools in many countries to promote STEM (science, technology, engineering and mathematics) education. The FIRST (For Inspiration and Recognition of Science and Technology) Robotics Competition was started by the famous American inventor in 1992 in the USA and has now become a popular international competition for children of high schools, middle schools as well as primary schools.

TLC mobile robots are designed and developed as examples of innovative product design and prototyping. They are built with representative and impactful real-world social and educational applications, e.g., solar-powered and mobile app-operated lawn mower robot for campus use which can expose students to robotics, smart trash can robot to support Swachh Bharat Mission of a Clean India, and mobile robot racing over the Internet for school children anywhere.

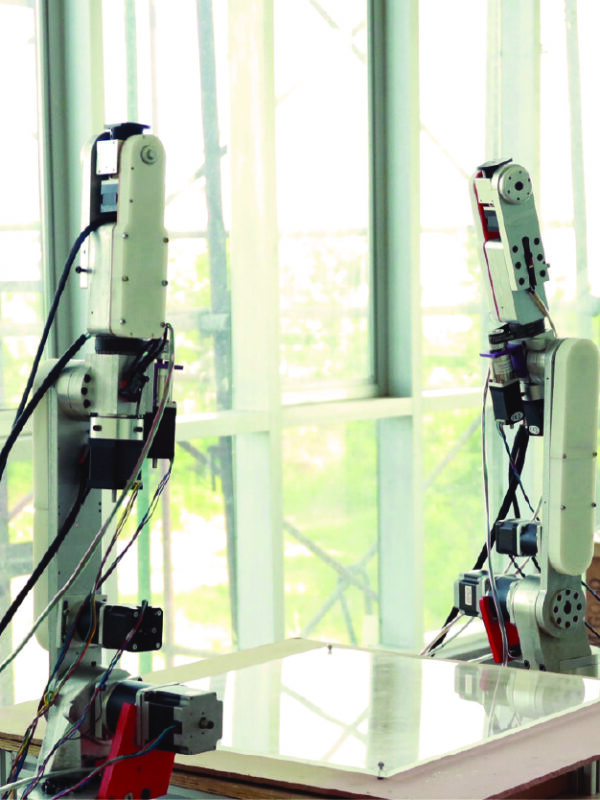

Robot Manipulators

Robots were initially crane-like industrial manipulators or arms, and along with automated guided vehicles (AGV) marked the beginning of industrial robots. Many academic institutions acquire very expensive commercial manipulators for laboratory instruction, but these systems have limited utility in an academic setting as they are difficult to customize for practical experiments in topics like modeling, kinematics, dynamics, path planning, control and sensing including vision, as information regarding construction, parameters, interfaces and software are not made available to end users.

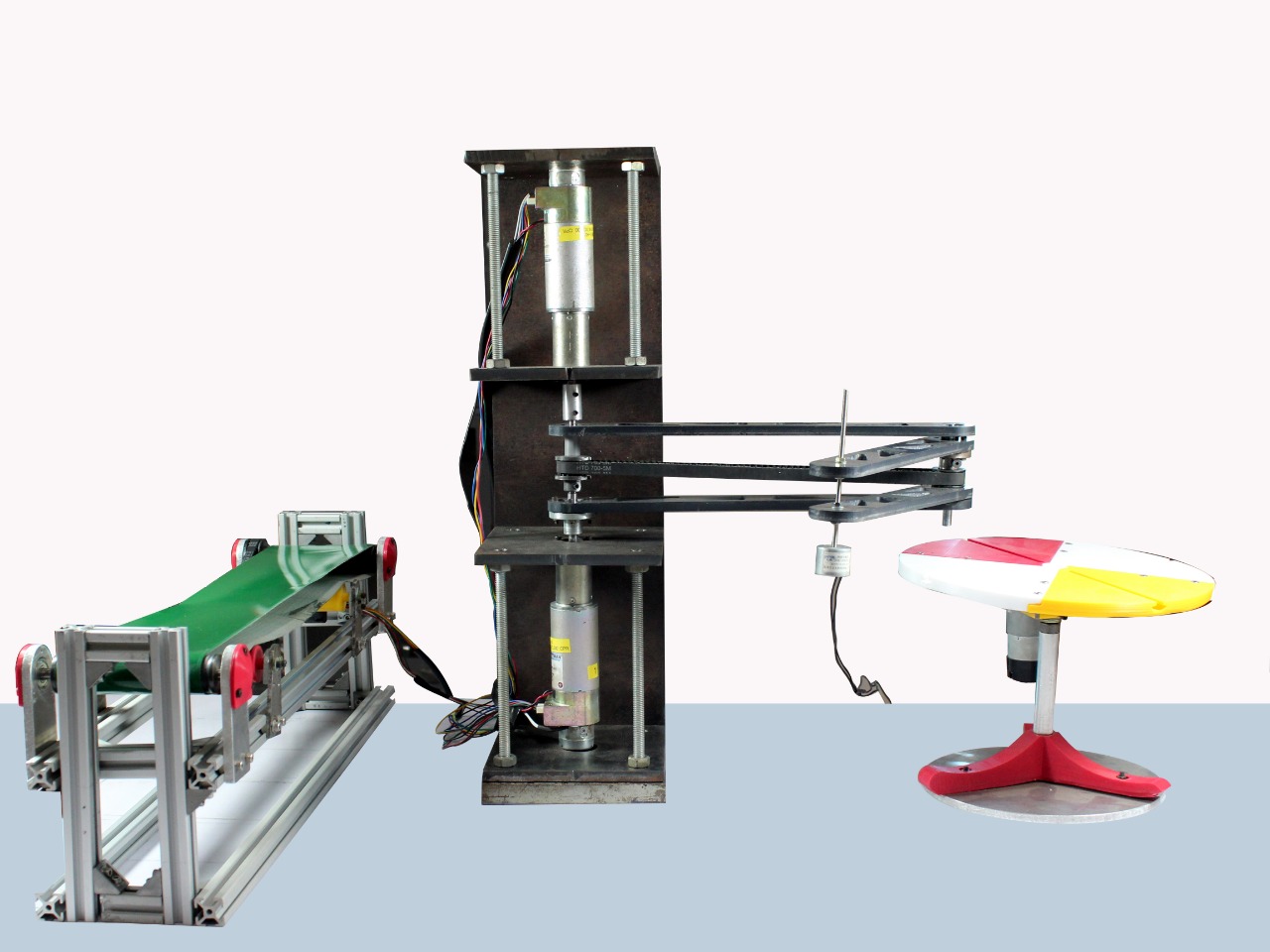

CIM Workcell

Computer Integrated Manufacturing (CIM) systems also known as Flexible Manufacturing Systems (FMS) are central to modern manufacturing industries. Most commercial didactic systems are very expensive and have limited applications like sorting, distribution, and so on. Our 2- and 3-link manipulators can be combined with industrial subsystems like rotary tables, conveyor belts, and machine vision to develop from scratch an educational CIM system at a fraction of the cost of commercial systems. Like many of TLC’s other laboratory learning modules, the CIM systems can also be customized, maintained and upgraded by end users.

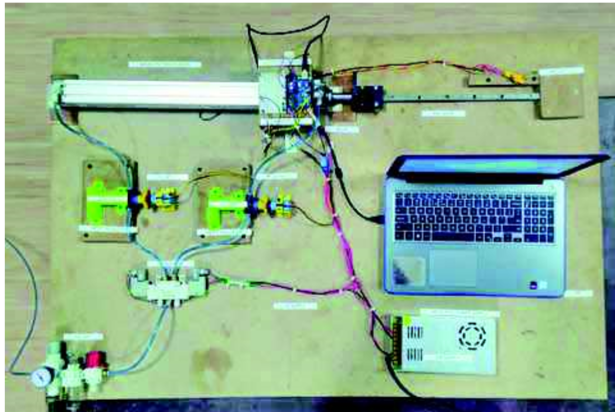

Pneumatic Systems

Pneumatics deals with compressed air-powered systems and occupies a niche in the manufacturing industry. Pneumatic actuators like cylinders have advantages of low-cost, high power-to-size and weight ratio, compliance and are hazard-proof as needed in many applications. Many students of mechanical/robotics/mechatronics/production/manufacturing engineering are not introduced to hands-on laboratory activities in pneumatics and the related discipline of hydraulics. Even existing pneumatic experimental systems involve manual connection and testing of components and subsystems, and so the learning outcomes are limited.

Smart Product Design

The term smart product refers to systems like the Internet of Things (IoT) technologies and embedded systems that use sensor data to build intelligence into the product. Popular commercial examples are the Nest smart thermometer, Philips connected toothbrush, Nike HyperAdapt shoes, etc. Many of the core components of the TLC developed modules – motors, sensors, and controllers – can be integrated with innovative systems leading to smart products, introducing students to innovative product design, prototyping, and manufacturing with entrepreneurship potential.

The smart trashcan robot is designed and developed as an example of smart product design. A prototype smart mosquito trap that identifies mosquitoes in situ is another example product presently under research and development.